In 3D printing, the correct adhesion of the first layer is crucial for a successful print. However, each material requires a slightly different approach. The build plate – its type and cleanliness – has an extreme influence on the model’s adhesion to the plate, but sometimes it is simply necessary to use some kind of adhesive spray to improve adhesion and keep the print on the plate.

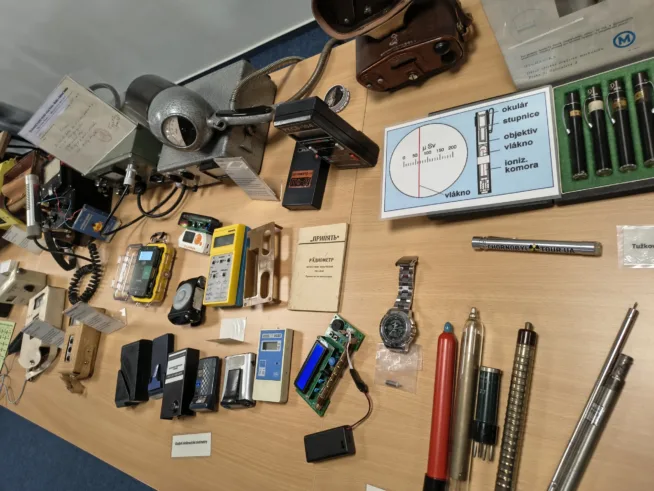

Václav Blaschke has come up with a small comparison of adhesive helpers – 3D sprays (the article has been modified from the original text for better readability).

Devil Design

- It has proven to be the best for PLA, PETG, CPE, and similar materials.

- The advantages are easy application, pleasant scent, and low price.

- Ideal for maintenance-free printing – no need for constant degreasing of the plate.

- In practice, it reliably works up to 90 °C (the manufacturer states up to 100 °C), but at higher temperatures, visible patterns may remain on the print.

- If you print often, I definitely recommend it.

3Dlac

- It is one of the more expensive products.

- The applicator disappointed me; a spray version might be better.

- I mainly use it for ASA and other materials that require a higher bed temperature.

- It has no significant odor, but over time it degrades and peels off the plate, which Devil Design does not do.

- Overall, I wasn’t too impressed.

Magigoo for PA

- The price is really high, but it works very well with nylon materials.

- It leaves no odor, and the applicator is practical.

Magigoo for PC

- Like the PA version, it is very expensive.

- It has an unpleasant odor, but it works on polycarbonate, and the applicator is again without issues.

Maintenance and Cleaning

- All these products can be easily washed off with warm water from both the print and the plate.

- In limited amounts, isopropyl alcohol (IPA) can be used to prevent prints’ outlines from remaining on the plate, which could transfer to the next print.

Special Print Plates

- There is also the option to use special plates (for example, from Prusa for PA, PC, PP).

- I have experience with the plate for PA – the adhesion is good, but there are often problems with calibrating the first layer.

- The plate must not be washed with IPA, which is impractical because you have to constantly carry it under water.

- Overall, I would rather not recommend this option.

Tip from chiptron.cz

How to clean the plate

– let the plate cool down completely

– remove the remnants of 3D printing – typically supports – using a plastic spatula or scraper (you can find many 3D models here).

– Moisten a soft, non-abrasive cloth or paper towel with isopropyl alcohol (ideally 70-99%) – If permitted by the plate manufacturer!

Gently wipe the entire surface of the plate to remove grease, dust, and plastic residues.

IPA evaporates quickly, so the surface will be dry within a few minutes.

– Avoid using abrasive materials (scouring pads, rough sponges) that could damage the surface.

– some plates can be washed with lukewarm water and a bit of dish soap – typically Dawn. After washing, rinse the plate with IPA (if permitted by the manufacturer).

A small comparison of adhesive helpers for 3D printing that I use. Unfortunately, each material wants something a little different; I haven’t found anything universal yet.

— Václav Blaschke (@vaclavblaschke) May 28, 2025

Devil Design: my favorite product for PLA, PETG, CPE, etc. for maintenance-free printing, so I don’t have to keep messing with… pic.twitter.com/I4o6tgBVfU